-40%

TBJ Model BD-2000 Bedding Dispenser - Rodent Cage Filling Machine - Saves Time!!

$ 6018.88

- Description

- Size Guide

Description

TBJ Model BD-2000 Bedding Dispenser - Rodent Cage Filling Machine - Saves Time!!In good working condition. Well cared for, stored indoors and in operation until last year. Recently cleaned and thoroughly tested.

This unit saves time and money! Ensuring that each cage has the proper amount of bedding consistently! You can put a new employee on the machine and they will be able to fill cages exactly how you want them!

Compatible bedding options:

*Sani-Chips

*Corn Cob

*loose, small diameter, lightweight bedding (no shredded aspen or flakes)

You are welcome to inspect the unit yourself in person or by video chat.

...

Video:

https://www.youtube.com/watch?v=B0akZ6k2zX0&t=7s

Description: The TBJ Model BD-2000 Bedding Dispenser is designed for the precise, highspeed filling of rodent cages with fresh, free flowing type-bedding material. Twin dispensing chutes provide simultaneous filling of two cages at a time. The operator simply pushes the cages against the trip lever switch to trigger the timed release of bedding material. An adjustable timer located on the control panel permits the operator to regulate the amount of bedding that is dispensed by setting the period of time that the dispensing chutes remain open. The timer may be programmed in seconds or tenths of seconds.

The total capacity of the BD-2000 is approximately 16 Cubic feet of chip-type, free flowing bedding material. The lower hopper will hold approximately 4cubic feet and the upper hopper will hold approximately 12 cubic feet.

During operation, the diminishing level of bedding material in the upper hopper is automatically replenished from the waiting supply held in the lower hopper. This is accomplished by means of a photoelectrical controlled, screw-type conveying system.

Dust created during operation or loading is effectively controlled by an internal dust filtration system. The dust filtration system includes (2) blowers with (2)removable, washable filters. Two amber indicator lights indicate that the blowers are in operation during the dispensing process.

Overall dimensions of the BD-2000 are 92”H x 40” W x 31 1/2”D. The maximum cage height is 12”. The electrical requirements are: 115V, 60 HZ, 1 PH, 15 AMP.

Compressed air requirements are provided by a built-in compressor system.

Standard Design and Construction:

A. Structure: All structural support is stainless steel. All sprockets, shafts, chains, etc. are carbon steel.

B. Hoppers: Both the lower storage bin and the upper storage bin are 14gauge type 304 stainless steel. Total hopper capacity is a minimum of 15cubic feet. Upper dispensing hopper is equipped with a removable cover for cleaning or maintenance.

C. Bedding Transfer System: Bedding is transferred from the lower storage bin to the upper dispensing hopper by a continuous shovel type screw conveyer. The transfer system operates automatically and is equipped with an on-off toggle switch on the control panel.

D: Work Surface: The work surface consists of a stainless steel 3/8 inch diameter welded rod grid. The grid is designed to permit the dumping of bagged bedding through the grid to the storage bin. The grid provides a work surface for the operator and allows spillage to fall through to be automatically returned to the dispensing hopper above. The grid is easily removable for cleaning or maintenance.

E. Dust Filtration: The unit is equipped with (2) blowers and (2) removable filters to capture and contain dust generated in the dispensing compartment. The filter is washable and reusable.

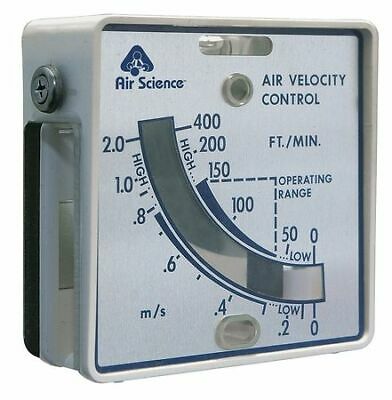

F. Controls: The operator’s control panel contains a main power On/Off selector switch, a Conveyor On/Off switch to control power to screw conveyor, a 0-10second automatic reset timer for precise metering and distribution of bedding and (2) amber indicator lights to indicate that the dust filtration blower are in the operational mode. The timer automatically resets itself after completion of a dispensing cycle.

G. An operation manual and parts list shall be supplied with the unit.

***Pickup from Rochester, NY is FREE (14468), We will palletize, strap and wrap the machine for you.***

****Delivery can be arranged for an additional cost. Please inquire****